Are You Looking For Tire Recycling Plant Cost?

- By Beston Recycling

- •

- 11 Dec, 2020

Are you presently looking for tire recycling plant cost? If you have, you may have come to the right place. There are actually over one billion passenger vehicles on the streets today. The truth is, over 300 million tires are discarded annually in america alone. Consider the amount of tires which can be discarded around the world! Where do you think these tires end up? The truth is, waste tires use up the majority of the space in landfills worldwide.

Discarded old tires are often left in riverbeds, empty lots, and backyards. They are certainly not only unsightly but will spread various diseases. These old tires become the location of rodents and insects that carry numerous diseases. For those who have old tires in your backyard, you may definitely find rodents and pests inside your garden and home. Old tires make good homes for such creatures. However, old tires that sit in empty lots for several years might cause the risk of fires. If you reside in the dry region, old tires can readily catch fire on account of accidents as well as other causes. Just imagine the possibility of old tires idling inside your backyard. That's why waste tires should be recycled to avoid such problems making a cash in on the company.

The round and hollow model of tires use up significant space in landfills. It takes hundreds of years for your rubber in old tires to decompose. That's why you need to recycle old tires to save lots of precious landfill space around the world. Pyrolysis plants come in handy to recycle old tires and save precious landfill space. You will certainly be doing your part for the eco-system and earning a handsome profit during this process if you purchase a quality tire recycling plant. This short article provides info on the tire recycling plant cost.

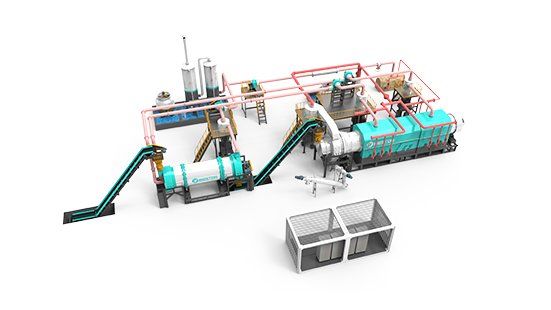

Determining the price of a tire recycling plant is fairly challenging. There are several factors affecting the price tag on a waste tire recycling plant. The standard of the spares from the machine is certainly one major factor. The plant usually includes a reactor, casing, oil sludge tank, oil gas manifold, oil storage tank, oil gas condenser, hydro-seal, dedusting system, and an automatic slag removal system. All of these parts must be produced from the highest quality raw materials. The ability in the machine can be another step to consider. Alternatively, the reputation and experience of the manufacturer will also affect the price of the plant.

You ought to be prepared to invest between $49,000 and $75,000 to get a quality tire pyrolysis plant. The purchase price may depend on the previously mentioned factors. The most important thing is usually to research your options before you shop to get the best recycling plant on the market. There are numerous tire recycling plant manufacturers available, but all are not top-notch. Your extensive research will let you pick the right product at a reasonable cost.

The aforementioned article provides important information on the expense of a top quality tire recycling plant available for sale.

Discarded old tires are often left in riverbeds, empty lots, and backyards. They are certainly not only unsightly but will spread various diseases. These old tires become the location of rodents and insects that carry numerous diseases. For those who have old tires in your backyard, you may definitely find rodents and pests inside your garden and home. Old tires make good homes for such creatures. However, old tires that sit in empty lots for several years might cause the risk of fires. If you reside in the dry region, old tires can readily catch fire on account of accidents as well as other causes. Just imagine the possibility of old tires idling inside your backyard. That's why waste tires should be recycled to avoid such problems making a cash in on the company.

The round and hollow model of tires use up significant space in landfills. It takes hundreds of years for your rubber in old tires to decompose. That's why you need to recycle old tires to save lots of precious landfill space around the world. Pyrolysis plants come in handy to recycle old tires and save precious landfill space. You will certainly be doing your part for the eco-system and earning a handsome profit during this process if you purchase a quality tire recycling plant. This short article provides info on the tire recycling plant cost.

Determining the price of a tire recycling plant is fairly challenging. There are several factors affecting the price tag on a waste tire recycling plant. The standard of the spares from the machine is certainly one major factor. The plant usually includes a reactor, casing, oil sludge tank, oil gas manifold, oil storage tank, oil gas condenser, hydro-seal, dedusting system, and an automatic slag removal system. All of these parts must be produced from the highest quality raw materials. The ability in the machine can be another step to consider. Alternatively, the reputation and experience of the manufacturer will also affect the price of the plant.

You ought to be prepared to invest between $49,000 and $75,000 to get a quality tire pyrolysis plant. The purchase price may depend on the previously mentioned factors. The most important thing is usually to research your options before you shop to get the best recycling plant on the market. There are numerous tire recycling plant manufacturers available, but all are not top-notch. Your extensive research will let you pick the right product at a reasonable cost.

The aforementioned article provides important information on the expense of a top quality tire recycling plant available for sale.

The conversion of organic materials into biochar can be something that is certainly done regularly now. This is due to from the technology that is certainly produce the machines that are capable of making the byproducts that are sold and subsequently burned. This biochar production equipment

is dependant on high technology, equipment that was not available decades ago. If you are looking at using machinery that could convert this type of material into charcoal, is ways to find this type of equipment for less.

How Come It Advantageous To Get This Equipment?

A primary reason that companies will make this type of investment is because they have a great deal waste matter work together with. It may be a substantial amount of plastic, or they are often liable for the municipal solid waste of your community. That is the situation, they should find a way to process all of it. There are many cases when they will likely have multiple companies, all of these will probably be producing this waste that could be transformed into this sort of fuel. If you have to have one or more of the machines deliver, the following is ways to look for the best ones.

So How Exactly Does Biochar Equipment Work?

Biochar equipment works within a specific way. To begin with, it is going to take that material and break it into smaller components. Second, it will probably separated all, into charcoal. Third, it is then going to be packaged and sold, and sold to places that are local, and in many cases a long way away. It can be a wonderful way to take this waste material, transformed into something that you can sell, and cash in on it from your business. More details: https://wasterecyclingplant.com/biomass-pyrolysis-plant/ .

Which Kind Of Biochar Equipment You Require?

The type of equipment you need will depend upon the volume of waste material that you are currently working with. As an illustration, in case you are in charge of a large number of a lot of material which are getting into your facility on a weekly basis, you really should put money into a full plant. However, you might have a very small facility. If that is the case, you will then want first of all a little machine. You can see how much of the biochar it is possible to produce, and if you want to undergo more of that waste material, you are able to invest in additional equipment depending on your preferences.

Where To Find Companies That Sell This Equipment

Funny firms that sell this equipment is easy. That is because countless companies are now producing it worldwide. It will be advantageous to see a different country, preferably the one that is nearby, that can sell you this for less. You really should head to their site, contact the people that sell it, and asked them queries about the machinery that they need to sell you. Inform them what type of waste material you might be working together with and they can direct you toward purchasing the best biochar production equipment available.

Once it is set up, you may be very easy to use. You will probably have multiple workers which will control every facet of the process. They will be able to prepare the material, method that material, and subsequently package something that you produce therefore we can be sold. Biochar is always will be in high demand. If you wish to have production equipment that can produce it to suit your needs, get more information today from reliable firms that are leaders in this industry.

How Come It Advantageous To Get This Equipment?

A primary reason that companies will make this type of investment is because they have a great deal waste matter work together with. It may be a substantial amount of plastic, or they are often liable for the municipal solid waste of your community. That is the situation, they should find a way to process all of it. There are many cases when they will likely have multiple companies, all of these will probably be producing this waste that could be transformed into this sort of fuel. If you have to have one or more of the machines deliver, the following is ways to look for the best ones.

So How Exactly Does Biochar Equipment Work?

Biochar equipment works within a specific way. To begin with, it is going to take that material and break it into smaller components. Second, it will probably separated all, into charcoal. Third, it is then going to be packaged and sold, and sold to places that are local, and in many cases a long way away. It can be a wonderful way to take this waste material, transformed into something that you can sell, and cash in on it from your business. More details: https://wasterecyclingplant.com/biomass-pyrolysis-plant/ .

Which Kind Of Biochar Equipment You Require?

The type of equipment you need will depend upon the volume of waste material that you are currently working with. As an illustration, in case you are in charge of a large number of a lot of material which are getting into your facility on a weekly basis, you really should put money into a full plant. However, you might have a very small facility. If that is the case, you will then want first of all a little machine. You can see how much of the biochar it is possible to produce, and if you want to undergo more of that waste material, you are able to invest in additional equipment depending on your preferences.

Where To Find Companies That Sell This Equipment

Funny firms that sell this equipment is easy. That is because countless companies are now producing it worldwide. It will be advantageous to see a different country, preferably the one that is nearby, that can sell you this for less. You really should head to their site, contact the people that sell it, and asked them queries about the machinery that they need to sell you. Inform them what type of waste material you might be working together with and they can direct you toward purchasing the best biochar production equipment available.

Once it is set up, you may be very easy to use. You will probably have multiple workers which will control every facet of the process. They will be able to prepare the material, method that material, and subsequently package something that you produce therefore we can be sold. Biochar is always will be in high demand. If you wish to have production equipment that can produce it to suit your needs, get more information today from reliable firms that are leaders in this industry.

If you are planning to get started on your own tire recycling business

, there are actually certain things you should do before investing a considerable sum of money in this project. Thankfully, you might be on the right course when you are looking over this article so that you are keen to know what you should do to be able to start a tire recycling business. The good thing is that Internet is full of helpful resources that can help you receive a hang of the things needs to be done in order to start and manage a profitable tire recycling business.

Tire recycling has been done for decades but there is an enormous opportunity within this business now as waste tires are getting to be a large problem for most of the cities around the globe. Due to deficiency of interest of entrepreneurs in this line of business, most cities handled the waste tire problem by dumping loads of waste tires within the landfills but those landfills are overflowing now, and municipalities and cities around the globe are eager to find ways to remove those huge mounds of waste tires.

One technology which has found favor with city officials around the world is tire pyrolysis. It’s a clean technology and a highly effective one at converting waste tires into something useful. Moreover, it’s a profitable technology driven business where driven entrepreneurs might help make a difference for the environment and earn an outstanding return of investment. However, your tire recycling business according to pyrolysis process will probably be successful only after it is set up correctly after proper research.

Start by preparing a business plan. If you don’t know much concerning this industry or pyrolysis technology , consider hiring the assistance of a consultant having been active within this industry for several years. They will help you know the nitty-gritty of establishing a new plant and operating it profitably. The technology found in the pyrolysis plant you select will be crucial for the prosperity of your business. Therefore, you can start researching various kinds of models sold by different companies and the pros and cons of all these models, and why it seems sensible to invest in a selected type rather than others.

Work out how much capacity you will require in the end and why it makes sense to choose a plant with optimum capacity as an alternative to all the capacity that you can afford to buy today. If you find yourself investing in a huge capacity that is better than needed, it is going to impact the operational efficiency from the plant which will modify the bottom-brand of your business. Similarly, energy efficiency, degree of automation as well as other such factors could have a huge impact over time. Therefore, carefully study different kinds of plants offered by manufacturers and choose one only after carefully considering the pros and cons of every type.

In addition, you have got to discover accessibility to power, water, labor, land as well as other such things required to setup and operate this business. The best way to start up a brand-new company is always to tie with an advisor or even an experienced person in this industry as a way to learn everything you should learn about putting together and operating a profitable tire recycling plant .

To conclude, concentrate on creating a foolproof strategic business plan by carefully analyzing the long-term price of raw materials plus the prices for that end products generated through the pyrolysis process. Utilize the assistance of a specialist in this line of help creating a well-researched and well thought out strategic business plan. Do not jump into this business without doing proper research as that may be unlikely to terminate well.

Tire recycling has been done for decades but there is an enormous opportunity within this business now as waste tires are getting to be a large problem for most of the cities around the globe. Due to deficiency of interest of entrepreneurs in this line of business, most cities handled the waste tire problem by dumping loads of waste tires within the landfills but those landfills are overflowing now, and municipalities and cities around the globe are eager to find ways to remove those huge mounds of waste tires.

One technology which has found favor with city officials around the world is tire pyrolysis. It’s a clean technology and a highly effective one at converting waste tires into something useful. Moreover, it’s a profitable technology driven business where driven entrepreneurs might help make a difference for the environment and earn an outstanding return of investment. However, your tire recycling business according to pyrolysis process will probably be successful only after it is set up correctly after proper research.

Start by preparing a business plan. If you don’t know much concerning this industry or pyrolysis technology , consider hiring the assistance of a consultant having been active within this industry for several years. They will help you know the nitty-gritty of establishing a new plant and operating it profitably. The technology found in the pyrolysis plant you select will be crucial for the prosperity of your business. Therefore, you can start researching various kinds of models sold by different companies and the pros and cons of all these models, and why it seems sensible to invest in a selected type rather than others.

Work out how much capacity you will require in the end and why it makes sense to choose a plant with optimum capacity as an alternative to all the capacity that you can afford to buy today. If you find yourself investing in a huge capacity that is better than needed, it is going to impact the operational efficiency from the plant which will modify the bottom-brand of your business. Similarly, energy efficiency, degree of automation as well as other such factors could have a huge impact over time. Therefore, carefully study different kinds of plants offered by manufacturers and choose one only after carefully considering the pros and cons of every type.

In addition, you have got to discover accessibility to power, water, labor, land as well as other such things required to setup and operate this business. The best way to start up a brand-new company is always to tie with an advisor or even an experienced person in this industry as a way to learn everything you should learn about putting together and operating a profitable tire recycling plant .

To conclude, concentrate on creating a foolproof strategic business plan by carefully analyzing the long-term price of raw materials plus the prices for that end products generated through the pyrolysis process. Utilize the assistance of a specialist in this line of help creating a well-researched and well thought out strategic business plan. Do not jump into this business without doing proper research as that may be unlikely to terminate well.

When you're buying a pulp molding machine

, you'll desire to be aware of the maker that made the appliance. Brand names is surely an indicator of quality, especially when you're buying heavy equipment. These are a few of the countless reasons you'll want to pay attention to brands when you're creating a purchase such as this.

Buying From Great Brands Will Assist You To Acquire More For Your Money

Buying costly equipment is always a danger. However, if you purchase coming from a brand that you could trust, you'll be capable of minimize the quantity of risk you're taking on.

You won't really need to be cautious about excellent deals if you notice a respected brand name. You'll realize that this product you're buying will meet your standards. Buying in the right brand will assist you to find more cheaper.

When You Order From A Top Manufacturer, You'll Really Know What You're Getting

The ideal brands that product pulp molding machines, such as egg carton machine , use a long track record. You'll have the ability to glance at the brand's history and get yourself a clearer picture of the items their equipment is like.

When you're purchasing expensive equipment like this, you shouldn't take any chances. Make sure do you know what you're expending money, and you need to feel just like you're using that money wisely. Buying coming from a famous and respected manufacturer means you'll know exactly what to expect.

Many Top Manufacturers Offer After-Purchase Service

If you have troubles with the machine after it arrives, you'll want to make certain that you'll be capable of resolve those problems immediately. That's another benefit top brands can offer. On many occasions, these brands will continue to offer customer service after you're purchased your equipment.

In some instances, these brands offer extensive warranties, which means your equipment is going to be protected. Discover more about what brands offer to be able to see what sort of protection you'll have. Possessing this additional protection can provide you with assurance.

Once You Buy From A Respected Brand, It May Be Easier To Get Replacement Parts

If you want to replace all of your machine's parts at some time or any other, you'll intend to make sure you'll have the capacity to accomplish that without having issue. If you opt for coming from a lesser-known brand, purchasing replacement parts may be expensive or difficult.

Considering that the top brands often sell their products and services throughout the world, it shouldn't be difficult to get replacement parts if you want them. This implies you'll be capable of repair your machine with minimal issues. Repairs are likely to be necessary sooner or later in the long run, which is the reason you'll want to ensure that repairs won't be a hassle for you.

Don't settle when you're buying pulp molding equipment. Instead, come up with a point of buying from one of several top manufacturers that produces this type of machinery. If you opt for the thing you need coming from a highly respected manufacturer, you'll have fewer issues and will also be happier with the equipment you choose.

Buying From Great Brands Will Assist You To Acquire More For Your Money

Buying costly equipment is always a danger. However, if you purchase coming from a brand that you could trust, you'll be capable of minimize the quantity of risk you're taking on.

You won't really need to be cautious about excellent deals if you notice a respected brand name. You'll realize that this product you're buying will meet your standards. Buying in the right brand will assist you to find more cheaper.

When You Order From A Top Manufacturer, You'll Really Know What You're Getting

The ideal brands that product pulp molding machines, such as egg carton machine , use a long track record. You'll have the ability to glance at the brand's history and get yourself a clearer picture of the items their equipment is like.

When you're purchasing expensive equipment like this, you shouldn't take any chances. Make sure do you know what you're expending money, and you need to feel just like you're using that money wisely. Buying coming from a famous and respected manufacturer means you'll know exactly what to expect.

Many Top Manufacturers Offer After-Purchase Service

If you have troubles with the machine after it arrives, you'll want to make certain that you'll be capable of resolve those problems immediately. That's another benefit top brands can offer. On many occasions, these brands will continue to offer customer service after you're purchased your equipment.

In some instances, these brands offer extensive warranties, which means your equipment is going to be protected. Discover more about what brands offer to be able to see what sort of protection you'll have. Possessing this additional protection can provide you with assurance.

Once You Buy From A Respected Brand, It May Be Easier To Get Replacement Parts

If you want to replace all of your machine's parts at some time or any other, you'll intend to make sure you'll have the capacity to accomplish that without having issue. If you opt for coming from a lesser-known brand, purchasing replacement parts may be expensive or difficult.

Considering that the top brands often sell their products and services throughout the world, it shouldn't be difficult to get replacement parts if you want them. This implies you'll be capable of repair your machine with minimal issues. Repairs are likely to be necessary sooner or later in the long run, which is the reason you'll want to ensure that repairs won't be a hassle for you.

Don't settle when you're buying pulp molding equipment. Instead, come up with a point of buying from one of several top manufacturers that produces this type of machinery. If you opt for the thing you need coming from a highly respected manufacturer, you'll have fewer issues and will also be happier with the equipment you choose.

Monitoring the condition of any company is imperative in order to earn more income every year. If you understand the problems you have, and also the areas what your location is succeeding, you can make use of these details. The same is true for almost any machinery that you will be using. You must do regular reports to keep the machinery, look for problems, as well as enhance these areas allowing you to have better results. You could do if you are going to invest in a paper egg tray machine

. This is how you can produce project reports.

What Will The Project Report Explain To You?

These reports are likely to monitor every aspect of this process. It can start with the pulp making machine. It will tell you in case the entire process is functioning well, and in addition give you exact reports on how much of that material is now being produced each and every day. Next, you will possess a readout of the levels of egg trays you are producing. This can be typically based on the volume of egg tray making machines that you may have in your facility. The report will summarize the whole amount of trays which are being produced daily. Finally, also you can monitor what occurs for the trays after they are out from the system. This is typically carried out to see how many actual eggs are being sent out of the facility.

Exactly Why Are These Reports Important?

The egg tray manufacturing project report is important for two different reasons. To begin with, it's nice to learn how everything is running. By monitoring the way your entire product is functioning, and all the various components, it is possible to gradually enhance your production levels. Second, it can identify problematic areas that may need repairs. You could place your workers on those areas, have the adjustments, and initiate to view a benefit from this kind of monitoring. These reports will certainly be useful for finding out where these issues are to enable you to maintain as well as accelerate your production levels.

Do Many Of These Machines Produce Reports?

Not all of this equipment is planning to produce most of these reports. Those that are exceptionally advanced certainly well. They may have computer systems that are monitoring every factor of your pc, to simply how much electricity is being used. If you may get a very detailed report, this will help your business be more productive with time. However, you possibly will not have enough cash for the most advanced machinery. If that is the situation, then you should do manual reporting by yourself, monitoring each a part of your facility throughout the day.

Regardless how you can actually generate a project report, these details is invaluable. It enables you to identify problems that may be fixed rapidly, eventually helping your organization be a little more successful. If you are producing many egg trays every single day, it is actually advantageous to have a manual egg tray manufacturing unit . In that way, you can have groups of professionals repair issues that are identified in order that you not have any difficulties with your production.

What Will The Project Report Explain To You?

These reports are likely to monitor every aspect of this process. It can start with the pulp making machine. It will tell you in case the entire process is functioning well, and in addition give you exact reports on how much of that material is now being produced each and every day. Next, you will possess a readout of the levels of egg trays you are producing. This can be typically based on the volume of egg tray making machines that you may have in your facility. The report will summarize the whole amount of trays which are being produced daily. Finally, also you can monitor what occurs for the trays after they are out from the system. This is typically carried out to see how many actual eggs are being sent out of the facility.

Exactly Why Are These Reports Important?

The egg tray manufacturing project report is important for two different reasons. To begin with, it's nice to learn how everything is running. By monitoring the way your entire product is functioning, and all the various components, it is possible to gradually enhance your production levels. Second, it can identify problematic areas that may need repairs. You could place your workers on those areas, have the adjustments, and initiate to view a benefit from this kind of monitoring. These reports will certainly be useful for finding out where these issues are to enable you to maintain as well as accelerate your production levels.

Do Many Of These Machines Produce Reports?

Not all of this equipment is planning to produce most of these reports. Those that are exceptionally advanced certainly well. They may have computer systems that are monitoring every factor of your pc, to simply how much electricity is being used. If you may get a very detailed report, this will help your business be more productive with time. However, you possibly will not have enough cash for the most advanced machinery. If that is the situation, then you should do manual reporting by yourself, monitoring each a part of your facility throughout the day.

Regardless how you can actually generate a project report, these details is invaluable. It enables you to identify problems that may be fixed rapidly, eventually helping your organization be a little more successful. If you are producing many egg trays every single day, it is actually advantageous to have a manual egg tray manufacturing unit . In that way, you can have groups of professionals repair issues that are identified in order that you not have any difficulties with your production.

Coconut shell charcoal features a high value available in the market because it has several uses. When you know learning to make coconut shell charcoal, you can make an excellent benefit from the merchandise. For those who have a lot of coconut shell waste, you should look at buying a coconut shell charcoal machine

. It is going to recycle the shells which will help prevent them from being disposed of from the environment. A coconut shell charcoal-making company is an eco-friendly project that will assist make money while protecting the surroundings as well. This short article provides information on how to produce coconut shell charcoal.

Carbonization will be the technology that is utilized to convert coconut shells into charcoal. Coconut shells, sawdust, rice husk, along with other carbon-containing raw materials can be carbonized into charcoal when they proceed through an operation of pyrolysis. You need to buy a carbonization machine for this reason. A carbonization machine is often known as a charcoal making machine. It's a higher-quality but low energy consuming machine. You can produce high-quality charcoal with the aid of this machine. The device is very efficient and may help increase your profits with time. The following is how a charcoal making machine is commonly used to make coconut shell charcoal:

. The coconut shells will be shredded into small pieces with a diameter of 20 mm

. The conveyor will feed the shredded coconut shells towards the quantitative feeder

. The feeder feeds the bits of coconut shells into the drying host from the machine

. The bits of coconut shells goes by way of a procedure of flash steaming and drying inside the drying host

. The bits of shells will directly fall down to the charcoal making furnace - which happens to be located within the drying host

. The carbonization host is heated to ensure an increased temperature inside the host - this is important for the biomass pyrolysis and decomposition to take place

. Along the way, coconut shells are carbonized into charcoals

. After cleansing and de-sulfurization, you will definitely get clean charcoal

Coconut shell charcoal is popular in several industries like the food industry, agriculture, cosmetics, and drinking water projects. On the other hand, the most up-to-date research indicates that coconut shell charcoal could be used as fuel, etc.

A quality charcoal making machine carries a higher efficiency and productivity rate. They have a unique double-layer structure to enhance the lifespan from the machine. The 2 main elements of the device will be the interior layer for drying host and also the exterior layer for carbonization. The most recent machines enables you to save money as a result of energy-efficient qualities of the product. Make sure you select a high-quality biochar making machine in a reasonable price. The aforementioned article provides information about how would you make coconut shell charcoal.

Carbonization will be the technology that is utilized to convert coconut shells into charcoal. Coconut shells, sawdust, rice husk, along with other carbon-containing raw materials can be carbonized into charcoal when they proceed through an operation of pyrolysis. You need to buy a carbonization machine for this reason. A carbonization machine is often known as a charcoal making machine. It's a higher-quality but low energy consuming machine. You can produce high-quality charcoal with the aid of this machine. The device is very efficient and may help increase your profits with time. The following is how a charcoal making machine is commonly used to make coconut shell charcoal:

. The coconut shells will be shredded into small pieces with a diameter of 20 mm

. The conveyor will feed the shredded coconut shells towards the quantitative feeder

. The feeder feeds the bits of coconut shells into the drying host from the machine

. The bits of coconut shells goes by way of a procedure of flash steaming and drying inside the drying host

. The bits of shells will directly fall down to the charcoal making furnace - which happens to be located within the drying host

. The carbonization host is heated to ensure an increased temperature inside the host - this is important for the biomass pyrolysis and decomposition to take place

. Along the way, coconut shells are carbonized into charcoals

. After cleansing and de-sulfurization, you will definitely get clean charcoal

Coconut shell charcoal is popular in several industries like the food industry, agriculture, cosmetics, and drinking water projects. On the other hand, the most up-to-date research indicates that coconut shell charcoal could be used as fuel, etc.

A quality charcoal making machine carries a higher efficiency and productivity rate. They have a unique double-layer structure to enhance the lifespan from the machine. The 2 main elements of the device will be the interior layer for drying host and also the exterior layer for carbonization. The most recent machines enables you to save money as a result of energy-efficient qualities of the product. Make sure you select a high-quality biochar making machine in a reasonable price. The aforementioned article provides information about how would you make coconut shell charcoal.

Are you presently trying to get the best egg tray machine for sale

on the market? If you're considering purchasing one of thee machines, you'll definitely would like to find a number of the top options available on the market. Here's tips on how to find fantastic devices that meet your needs.

Research Your Choices

Start learning more about the machines that happen to be out there. If you have additional information relating to your options, it'll be easier for you to help make the best choice.

What kind of information will you need to seek out? You'll need to see how machines operate, and you'll also want to see how many egg cartons the machines are capable of producing each hour.

The easiest way to have this facts are to learn the merchandise descriptions of egg cartons. The item descriptions needs to have a wealth of useful information.

Consider Your Personal Needs

While all of these machines serve a similar basic purpose, not all the machine operates in the same manner. You need to take into consideration what you're searching for.

You'll want to find out the ideal size to your paper pulp molding machine . You'll also need to decide regardless of whether you want a machine with specific features. Once you know what to consider, you'll be able to select a terrific product.

Get A Machine Which Was Manufactured By A Trusted Manufacturer

You need to make sure you can rely on the maker you may have chosen. You ought to work with a manufacturer that has a past of producing excellent, top quality products.

In the event you can't trust the maker that made your machine, you're probably going to encounter problems. You ought to make an effort to find a few of the top manufacturers of these kinds of machines. If you pick a piece of equipment that had been produced from a great manufacturer, you'll more likely be happy with your purchase.

Buy From A Vendor That One Could Trust

You shouldn't purchase new machine from just any vendor. You must search for a vendor that has the types of products that you want. You must also find a vendor that is recognized for being reliable.

If you don't know a great deal with regards to a vendor, you'll interested in learning more before you purchase anything from them. You shouldn't make any assumptions regarding a vendor. It's always better to find more info so that you'll know whether a vendor is worth buying from.

Once you learn people with purchased these kinds of machines before, you must inquire further about the vendors they normally use. See when they can point you toward a reliable and reliable vendor.

Finding the optimum egg tray machine or egg carton machine for sale might take some time. You can't be prepared to find what you wish immediately you'll probably have to check out a number of machines before you find something that's a good fit for you personally. If you take your time and effort and here are some ideas, you must eventually manage to find among the best machines on the market.

Research Your Choices

Start learning more about the machines that happen to be out there. If you have additional information relating to your options, it'll be easier for you to help make the best choice.

What kind of information will you need to seek out? You'll need to see how machines operate, and you'll also want to see how many egg cartons the machines are capable of producing each hour.

The easiest way to have this facts are to learn the merchandise descriptions of egg cartons. The item descriptions needs to have a wealth of useful information.

Consider Your Personal Needs

While all of these machines serve a similar basic purpose, not all the machine operates in the same manner. You need to take into consideration what you're searching for.

You'll want to find out the ideal size to your paper pulp molding machine . You'll also need to decide regardless of whether you want a machine with specific features. Once you know what to consider, you'll be able to select a terrific product.

Get A Machine Which Was Manufactured By A Trusted Manufacturer

You need to make sure you can rely on the maker you may have chosen. You ought to work with a manufacturer that has a past of producing excellent, top quality products.

In the event you can't trust the maker that made your machine, you're probably going to encounter problems. You ought to make an effort to find a few of the top manufacturers of these kinds of machines. If you pick a piece of equipment that had been produced from a great manufacturer, you'll more likely be happy with your purchase.

Buy From A Vendor That One Could Trust

You shouldn't purchase new machine from just any vendor. You must search for a vendor that has the types of products that you want. You must also find a vendor that is recognized for being reliable.

If you don't know a great deal with regards to a vendor, you'll interested in learning more before you purchase anything from them. You shouldn't make any assumptions regarding a vendor. It's always better to find more info so that you'll know whether a vendor is worth buying from.

Once you learn people with purchased these kinds of machines before, you must inquire further about the vendors they normally use. See when they can point you toward a reliable and reliable vendor.

Finding the optimum egg tray machine or egg carton machine for sale might take some time. You can't be prepared to find what you wish immediately you'll probably have to check out a number of machines before you find something that's a good fit for you personally. If you take your time and effort and here are some ideas, you must eventually manage to find among the best machines on the market.

Tyre recycling and disposal is a business with huge demand but almost no supply. Therefore, which makes it your primary or side business will more than likely supply you with a decent income. Of course, as with every business launch, to ensure success, you must it properly. That's why in this article, we will share information on how to launch your own personal tyre recycling business

.

Steps to Launching a Tyre Recycling Business

1. Understand the Market

The first task is to identify prospects for that materials you plan to recycle. This states the level of equipment to purchase and also the recycled products you can expect to offer. Industrial heating and incinerator plants utilize rubber crumbs for tyre-derived fuels. Road construction companies require shredded rubber crumbs to mix with hot asphalt. Recycled rubber provides a robust surface for areas like running tracks or playgrounds. Companies ideally recover high-value materials like steel, oil, and carbon black. Never to forget the most obvious application, producing new tires.

2. Locate a Site

The next phase is to identify a rural or industrial location where you may get, store and process huge variety of tyres in the safe manner. Tyre recycling is a dusty and noisy process, and thus, you need to check zoning and noise restrictions in the region. The location should provide quick access for trucks delivering the waste material and collecting the recycled ones. Be sure to have proper fire prevention measures and fire fighting equipment at your location.

3. Get Permits and Licenses

It is actually important to look at your region's requirements for tyre recycling plant to prevent entering into legal trouble. Each state has varying licensing guidelines with varying requirements for financial assurance, registration, storage, processing and also tyre pile clean-up, based on the EPA (Environmental Protection Agency). You may also have to get permits related to fire safety, public health insurance and air quality.

4. Set Up the Recycling Plant

Buy or rent used or new equipment for processing waste tyres in your new recycling plant. To deal with incoming materials and tyres on-site, you'll need to invest in a forklift. Additionally, you will need a tyre shredder with a set of varying size screens so that you can meet your clients' specific needs. Large-scale shredders often incorporate industrial magnets that separate metals from rubber, thus maximizing the recyclable products. You'll must also get containers for storing the recycled materials.

5. Find Types of Feedstock

It goes without proclaiming that a constant way to obtain used tyres is critical in your recycling business. So, get in touch with companies or organizations that require to get rid of vehicle tyres, including tire retailers, car rental firms, service centers, taxi firms, bus & coach operators, trucking and logistics firms, along with organizations with fleets of vehicles.

Consider listing your facilities in local company directories as a way to advertise your business. You can also leverage the strength of social media. In the event you give a used tyre collection service, aim to produce a supply base in a radius of 150 miles. This is basically the recommended distance for the profitable tyre recycling plant. More details about the cost: https://wasterecyclingplant.com/waste-tyre-recycling-plant-cost/ .

Steps to Launching a Tyre Recycling Business

1. Understand the Market

The first task is to identify prospects for that materials you plan to recycle. This states the level of equipment to purchase and also the recycled products you can expect to offer. Industrial heating and incinerator plants utilize rubber crumbs for tyre-derived fuels. Road construction companies require shredded rubber crumbs to mix with hot asphalt. Recycled rubber provides a robust surface for areas like running tracks or playgrounds. Companies ideally recover high-value materials like steel, oil, and carbon black. Never to forget the most obvious application, producing new tires.

2. Locate a Site

The next phase is to identify a rural or industrial location where you may get, store and process huge variety of tyres in the safe manner. Tyre recycling is a dusty and noisy process, and thus, you need to check zoning and noise restrictions in the region. The location should provide quick access for trucks delivering the waste material and collecting the recycled ones. Be sure to have proper fire prevention measures and fire fighting equipment at your location.

3. Get Permits and Licenses

It is actually important to look at your region's requirements for tyre recycling plant to prevent entering into legal trouble. Each state has varying licensing guidelines with varying requirements for financial assurance, registration, storage, processing and also tyre pile clean-up, based on the EPA (Environmental Protection Agency). You may also have to get permits related to fire safety, public health insurance and air quality.

4. Set Up the Recycling Plant

Buy or rent used or new equipment for processing waste tyres in your new recycling plant. To deal with incoming materials and tyres on-site, you'll need to invest in a forklift. Additionally, you will need a tyre shredder with a set of varying size screens so that you can meet your clients' specific needs. Large-scale shredders often incorporate industrial magnets that separate metals from rubber, thus maximizing the recyclable products. You'll must also get containers for storing the recycled materials.

5. Find Types of Feedstock

It goes without proclaiming that a constant way to obtain used tyres is critical in your recycling business. So, get in touch with companies or organizations that require to get rid of vehicle tyres, including tire retailers, car rental firms, service centers, taxi firms, bus & coach operators, trucking and logistics firms, along with organizations with fleets of vehicles.

Consider listing your facilities in local company directories as a way to advertise your business. You can also leverage the strength of social media. In the event you give a used tyre collection service, aim to produce a supply base in a radius of 150 miles. This is basically the recommended distance for the profitable tyre recycling plant. More details about the cost: https://wasterecyclingplant.com/waste-tyre-recycling-plant-cost/ .

Even though many businesses opt to buy fully-automated egg tray making machines

, there are several good things about picking a manual model. The settings in fully-automated models may be significantly enhanced, however, for firms that have plenty of labor, this will not be a challenge. One of the many great things about manual egg tray making machines is because they are smaller and much easier to operate.

How Does A Manual Egg Tray Making Machine Work?

When compared with fully-automated models, manual machines are definitely more practical. This equipment is more compact and designed for businesses that only have to produce limited quantities at a time. However, these machines are fully capable of producing a few hundred trays with a bit of effort.

The first stage from the process involves mixing the pulp which will require manual labor. From here the pulp flows in a forming machine before they are sent to a heating area. The manual machines do not include a conveyor belt hence the trays have to be taken off manually.

Manual Egg Tray Making Machine - Affordability

When you compare fully automated machines to manual machines, price does play a huge role. The manual egg tray making machine costs significantly less in comparison to the automated versions. Using a manual machine, you spend to the components in addition to the machine size you might have chosen. The manual machines are best suitable for the firms which can be still at first stages. This equipment is generally more cost-effective and smaller, which suggests they occupy a lot less space. You also won't need a lot of space for the machine, especially when you have enough workers that you can train on ways to use the machine.

Four Systems Of The Manual Egg Tray Making Machine

The egg tray making machines include a pulp-making system, a forming system, a drying system, as well as the packing system.

The initial step involves placing waste paper in to the pulping machine. Water will then be included in make your pulp, which supplies a way to recycle old paper waste. From here the pulp will be screened into thin fibers inside the screening machine. Following the screening process, the pulp consistency is adjusted on the appropriate thickness and strength.

From this point the pulp is passed in a forming system . Many of the manual egg tray making machines have standard molds that have 30 holes. Your third stage of your process involves sending the wet trays on the drying system. Coal, gas, or diesel is usually used as the fuel to offer heat. The new air is commonly used to dry the egg trays. From this point the trays are removed manually and stacked, able to be sold.

Advantages Of A Manual Egg Tray Making Machine

Here is a review of the main benefits of the manual egg tray making machine:

- Fine quality at a reasonable price

- Long-service life

- Wide application for producing different types of trays (shoe, apple, or seed trays)

- Energy-saving system

How Does A Manual Egg Tray Making Machine Work?

When compared with fully-automated models, manual machines are definitely more practical. This equipment is more compact and designed for businesses that only have to produce limited quantities at a time. However, these machines are fully capable of producing a few hundred trays with a bit of effort.

The first stage from the process involves mixing the pulp which will require manual labor. From here the pulp flows in a forming machine before they are sent to a heating area. The manual machines do not include a conveyor belt hence the trays have to be taken off manually.

Manual Egg Tray Making Machine - Affordability

When you compare fully automated machines to manual machines, price does play a huge role. The manual egg tray making machine costs significantly less in comparison to the automated versions. Using a manual machine, you spend to the components in addition to the machine size you might have chosen. The manual machines are best suitable for the firms which can be still at first stages. This equipment is generally more cost-effective and smaller, which suggests they occupy a lot less space. You also won't need a lot of space for the machine, especially when you have enough workers that you can train on ways to use the machine.

Four Systems Of The Manual Egg Tray Making Machine

The egg tray making machines include a pulp-making system, a forming system, a drying system, as well as the packing system.

The initial step involves placing waste paper in to the pulping machine. Water will then be included in make your pulp, which supplies a way to recycle old paper waste. From here the pulp will be screened into thin fibers inside the screening machine. Following the screening process, the pulp consistency is adjusted on the appropriate thickness and strength.

From this point the pulp is passed in a forming system . Many of the manual egg tray making machines have standard molds that have 30 holes. Your third stage of your process involves sending the wet trays on the drying system. Coal, gas, or diesel is usually used as the fuel to offer heat. The new air is commonly used to dry the egg trays. From this point the trays are removed manually and stacked, able to be sold.

Advantages Of A Manual Egg Tray Making Machine

Here is a review of the main benefits of the manual egg tray making machine:

- Fine quality at a reasonable price

- Long-service life

- Wide application for producing different types of trays (shoe, apple, or seed trays)

- Energy-saving system

Eggs remain one of the more popular sources of protein across the world. They can be relatively cheap to generate and move from shelves fast, leading them to be a popular among both all scale farmers and larger commercial operations. However, transport and storage (along with display) of eggs can be a tricky business due to fragility of your product. One of the more popular ways to transport, store and display eggs is with the use of egg trays - and the most popular of these types of trays are the ones which are manufactured using waste pulp.

The application of waste paper and cardboard has a number of advantages for the manufacturer. The original source material (waste) is easily available and cheap to get. however, the actual egg carton manufacturing process may be more involved than many consumers realize.

The initial step along the way may be the pulping of the waste material. The waste materials fed into an hydraulic pulper where it is stirred and pulverized. The content that is utilized can consist of newspapers, office waste and an array of other waste paper types. However, all these can harbor impurities. to acquire a uniform and quality pulp these impurities are separated from your pulp using screens. Impurities for example sand may be especially problematic and therefore are there the focus of the screen process. Additives are brought to the pulp in order to guarantee how the material (when finally dried) is waterproof and contains anti-static properties.

The pulp will be introduced into a number of pools ahead of the following step which is the molding process.

This technique uses a number of vacuum pumps, compressors and the molding machines themselves. It really is these molding machines which are central to the entire process. Air compressors can also be utilized to help take away the moisture from the pulp so that you can optimize and streamlined the molding process. The workflow at this point becomes essential in order for the operation to continouly prepare the egg trays in a fashion that minimizes downtime and optimizes output.

After the molded product is taken from the molding machinery it is still wet. This calls for using drying machinery. An alternative to using this machinery is natural drying methods. This may reduce energy costs and is particularly becoming increasingly popular because of the fact that it is eco-friendly. However, it is actually cumbersome - and that is why many larger manufacturers still prefer the application of machinery as a way tospeed in the drying process.

Once this method has been completed the egg trays are packaged to become transported for the egg production facility.

The benefits to the usage of modern equipment in egg tray manufacturing include the lowering of waste. Waste material is fed into the production loop. The advantages are not only financial savings - but also provides for the production of a 'greener' product and education from the environmental impact of operations.

Eggs continue being extremely popular in diets across the world. In order to keep retail stores supppied having a superior product, the egg tray machine is important - and demand continues to increase.

The application of waste paper and cardboard has a number of advantages for the manufacturer. The original source material (waste) is easily available and cheap to get. however, the actual egg carton manufacturing process may be more involved than many consumers realize.

The initial step along the way may be the pulping of the waste material. The waste materials fed into an hydraulic pulper where it is stirred and pulverized. The content that is utilized can consist of newspapers, office waste and an array of other waste paper types. However, all these can harbor impurities. to acquire a uniform and quality pulp these impurities are separated from your pulp using screens. Impurities for example sand may be especially problematic and therefore are there the focus of the screen process. Additives are brought to the pulp in order to guarantee how the material (when finally dried) is waterproof and contains anti-static properties.

The pulp will be introduced into a number of pools ahead of the following step which is the molding process.

This technique uses a number of vacuum pumps, compressors and the molding machines themselves. It really is these molding machines which are central to the entire process. Air compressors can also be utilized to help take away the moisture from the pulp so that you can optimize and streamlined the molding process. The workflow at this point becomes essential in order for the operation to continouly prepare the egg trays in a fashion that minimizes downtime and optimizes output.

After the molded product is taken from the molding machinery it is still wet. This calls for using drying machinery. An alternative to using this machinery is natural drying methods. This may reduce energy costs and is particularly becoming increasingly popular because of the fact that it is eco-friendly. However, it is actually cumbersome - and that is why many larger manufacturers still prefer the application of machinery as a way tospeed in the drying process.

Once this method has been completed the egg trays are packaged to become transported for the egg production facility.

The benefits to the usage of modern equipment in egg tray manufacturing include the lowering of waste. Waste material is fed into the production loop. The advantages are not only financial savings - but also provides for the production of a 'greener' product and education from the environmental impact of operations.

Eggs continue being extremely popular in diets across the world. In order to keep retail stores supppied having a superior product, the egg tray machine is important - and demand continues to increase.

Paper egg trays are definitely the primary storage and transportation equipment for eggs. Eggs are fragile goods that can break, ultimately causing a tremendous loss for companies. The appliance that helps with the manufacturing of these items may be the egg tray making machine or egg carton making machine

. It will come in three different versions, all employing varying mechanisms of operations. You will encounter manual, fully automatic, and semi-automatic versions. The choice is entirely dependent on your requirements and financial capability. Nevertheless, all types assume a four-step process to achieve production. Please read on to locate more details on these stages.

Step One. Pulping.

The first stage of production will be the pulping phase. The pulping system works with other equipment just like a water pool and pulp beater to achieve its goal. The original step is always to fit the accessible waste paper within the collection, then the addition of water. The proportioning water has got to complement that from the raw material in order to avoid wastages. Also, it's to improve the performance of the next stage. The pulp beater will likely then mix the constituents to guarantee the formation of any uniform mixture. The procedure is time-consuming since it influences the caliber of output. Upon achievement in the desired consistency, it proceeds on the second phase.

Step Two. Molding.

The molding system is how the mix takes shape to make up the egg trays. The availability of pipes enables conveying the types of materials, which then gets released about the forming molds. One advantage of buying the egg tray making machine is that it is diverse. It could produce various products suited to eggs, fruits, shoes, and coffee cups. At this level, the content will land about the models, and with the aid of a vacuum pump, they will take the exact shape of the various tools. During the last stage, an aura compressor will blow air to detach them from the models. It is actually at this age how the administrator can conclude the capability of production.

Step Three.Drying.

It is the third stage of production comprising of three different models and platforms of drying. Natural drying may be the first type and transpires under the sun. The technique is perfect for companies dealing in small-scale manufacture of the crates. It can be time-consuming and can lead to inconveniences once the weather isn't favorable. The other two versions include metal and brick drying systems. They may be prompt and efficient, and you may either keep these things in single, double, or multilayered designs. Additionally, there is a conveyor belt to permit for even distribution of heat.

Step 4.Packaging.

The particular last step is the packaging and shipment in the commodities on the clients. This is a main part of automatic However, before that, they may move through a hot press. The reason is to get rid of air trapped within the crates and provide it a defined appearance.

As seen above, making egg crates using waste paper is quite extensive and requires attention to detail. However, it really is a lucrative business using a high potential to enhance your profits and widen your clients' network. More details: https://wasterecyclingplant.com/egg-tray-manufacturing-project-report-india/ .

Step One. Pulping.

The first stage of production will be the pulping phase. The pulping system works with other equipment just like a water pool and pulp beater to achieve its goal. The original step is always to fit the accessible waste paper within the collection, then the addition of water. The proportioning water has got to complement that from the raw material in order to avoid wastages. Also, it's to improve the performance of the next stage. The pulp beater will likely then mix the constituents to guarantee the formation of any uniform mixture. The procedure is time-consuming since it influences the caliber of output. Upon achievement in the desired consistency, it proceeds on the second phase.

Step Two. Molding.

The molding system is how the mix takes shape to make up the egg trays. The availability of pipes enables conveying the types of materials, which then gets released about the forming molds. One advantage of buying the egg tray making machine is that it is diverse. It could produce various products suited to eggs, fruits, shoes, and coffee cups. At this level, the content will land about the models, and with the aid of a vacuum pump, they will take the exact shape of the various tools. During the last stage, an aura compressor will blow air to detach them from the models. It is actually at this age how the administrator can conclude the capability of production.

Step Three.Drying.

It is the third stage of production comprising of three different models and platforms of drying. Natural drying may be the first type and transpires under the sun. The technique is perfect for companies dealing in small-scale manufacture of the crates. It can be time-consuming and can lead to inconveniences once the weather isn't favorable. The other two versions include metal and brick drying systems. They may be prompt and efficient, and you may either keep these things in single, double, or multilayered designs. Additionally, there is a conveyor belt to permit for even distribution of heat.

Step 4.Packaging.

The particular last step is the packaging and shipment in the commodities on the clients. This is a main part of automatic However, before that, they may move through a hot press. The reason is to get rid of air trapped within the crates and provide it a defined appearance.

As seen above, making egg crates using waste paper is quite extensive and requires attention to detail. However, it really is a lucrative business using a high potential to enhance your profits and widen your clients' network. More details: https://wasterecyclingplant.com/egg-tray-manufacturing-project-report-india/ .